Using matrix and complex materials can make the quality control procedures difficult. VeriVide provides innovative solutions so that quality is not compromised, no matter the material used.

Colour quality control procedures can be difficult in technical textiles, as they are produced from matrix or/and complex materials. VeriVide provides cost-effective and innovative solutions to accurately measure, reproduce, communicate, and assess colour and appearance of woven and non-woven fabrics, microfilament, polyester or nylon yarns and acrylic, polymer or carbon fibres.

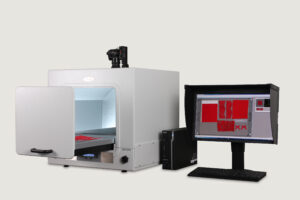

Measuring and evaluating colour and appearance digitally enables manufacturers to speed up colour development, share and communicate objective colour data across the globe and achieve colour consistency throughout their supply chain.

VeriVide’s equipment can be applied to helmets, gloves, seat covers for automotive, aerospace and other transport interiors, seat belts, airbags, parachutes, air balloons, carbon fibre, medical implants and prosthetics as well as many more products.

If you are at the start of your colour matching journey, we advise starting by choosing the correct colour standards. As master distributors of Pantone, RAL and NCS, we have the expertise and knowledge to guide your decision making. Contact us via email on colourstandards@verivide.com or call us on +44 (0)116 284 7790

If you have the correct colour standards but wish to know more about how our lighting cabinets and DigiEye software can benefit your colour matching process and how these elements can fit into your industry and product designs, please email us at enquiries@verivide.com or call +44 (0)116 284 7790.