What is metamerism

There’s a widely-used tale to explain just what metamerism is and how it has an effect on us, often without us initially realising it.

Imagine the scene: You’re getting dressed in the morning, you throw on a pair of black socks thinking they’re a perfect match, but it’s not until you arrive at work that you realise one of them is navy. That’s metamerism.

Another scenario could be that you are shopping for that new carpet you’ve been wanting for ages, you choose a lovely honey-coloured one in the store but, when it’s finally laid in your home, you’re shocked to see it’s more of a pallid grey. That colour is colour inconstant and so when compared to the original brand standard it will show metamerism.

What’s essentially happening – this phenomenon that is metamerism – is that colours are being viewed in different light sources. So, that carpet viewed under store lighting is going to look different when viewed under the different lights of your own home.

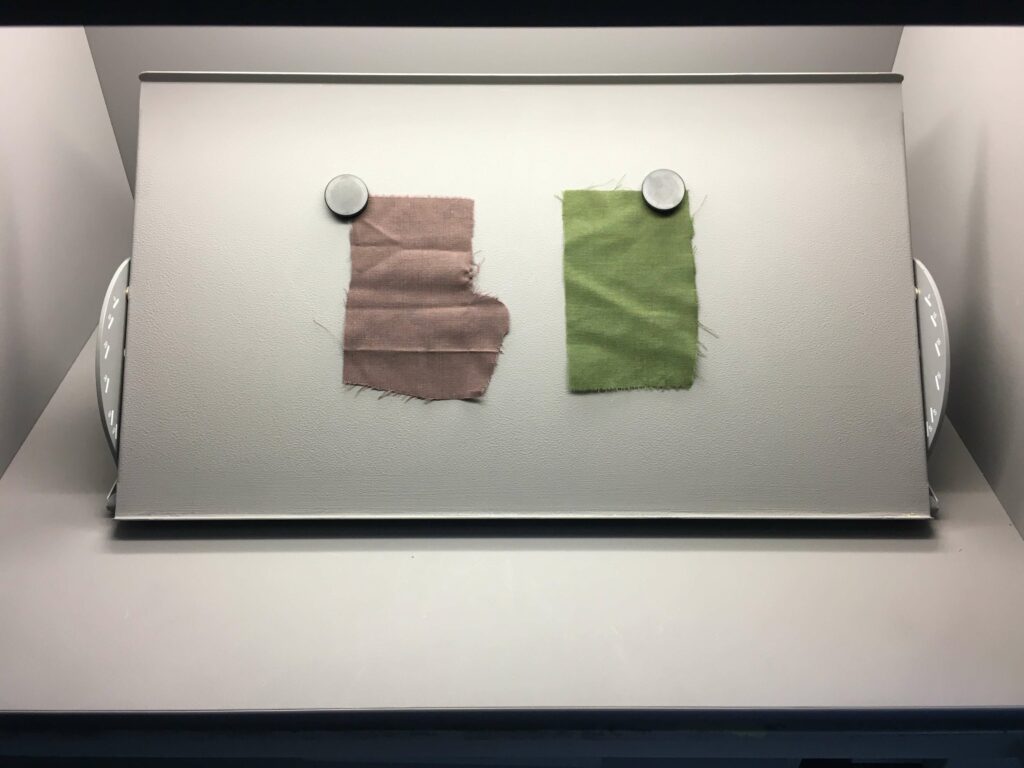

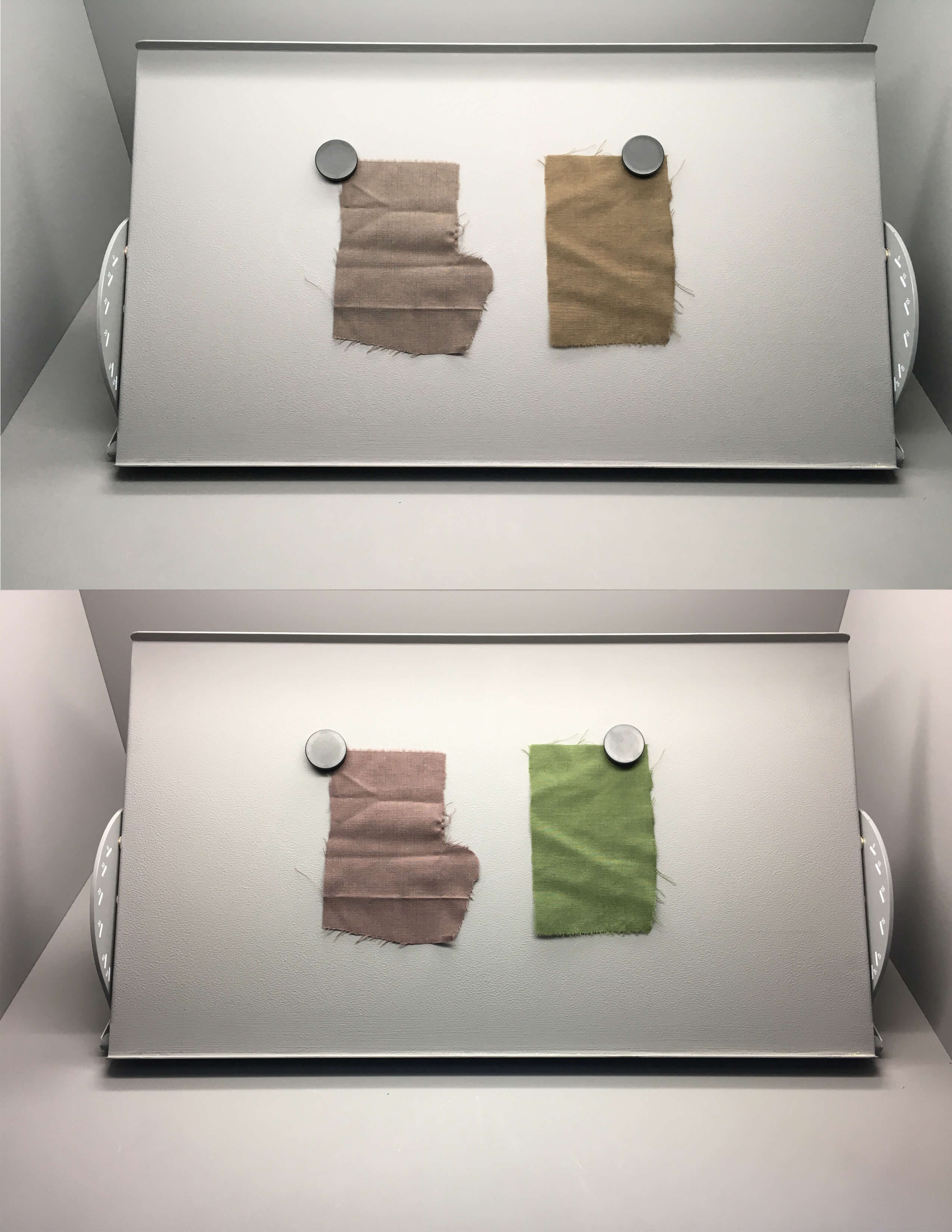

Two samples that appear to match each other under one light source may not match under a different light source if their spectral properties differ. This can be a problem where we want a standard and batch to match under a range of different light sources.

We’ve gone into more detail on a previous post about what metamerism is and why it occurs.

Why is measuring metamerism important?

In industries where colour matching or colour tolerances are vitally important, using materials that are metameric colour matches rather than spectral colour matches can prove to be a major problem.

What do we mean by that? Take the furniture industry as an example. When a sofa is being assembled on the production line, the fabric and exterior components may be manufactured to provide a good colour match under the designer’s office light source. But no sooner are those colour matches viewed under different light sources, such as artificial daylight, visual differences can occur.

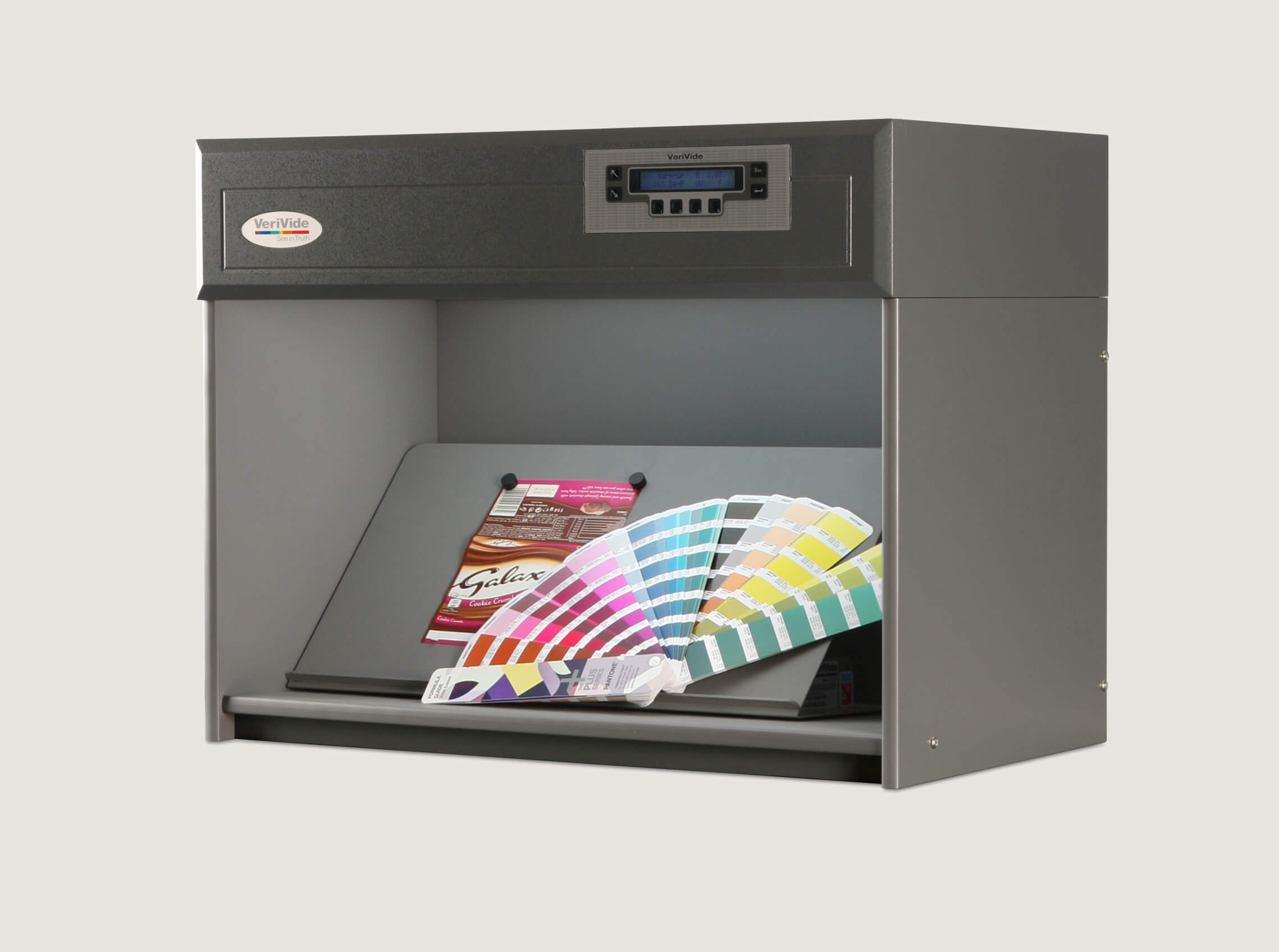

Image: Samples are assessed under different light sources in VeriVide’s Colour Assessment Cabinets

Colour accuracy is a problem for a vast array of industries. Aerospace, automotive, food & drink, textiles, plastics and many more rely on getting the right colour matches but end up experiencing similar problems. Take cars as another example. In this case, the vast array of substrates that must provide a colour match present a severe risk of metamerism. This, coupled with extremely stringent colour quality standards, makes automotive colour matching an extremely difficult procedure.

Image: Automotive components under VeriVide’s Colour Assessment Cabinets

In the paint industry, colour matches are often aimed at achieving a spectral colour match rather than just a metameric colour match under a given spectrum of light. A spectral colour match attempts to give two colours the same spectral reflectance characteristic, making them a good metameric match with a low degree of metamerism, thereby reducing the sensitivity of the resulting colour match to changes in lighting, or differences between observers.

Metamerism simply has to be closely monitored. And to manage metamerism during colour production, you have to know what causes it.

What tools can be used to measure metamerism?

We’ve established some of the scenarios where metamerism occurs and why it’s important to avoid it.

But how do we go about that? What are the best ways to measure metamerism?

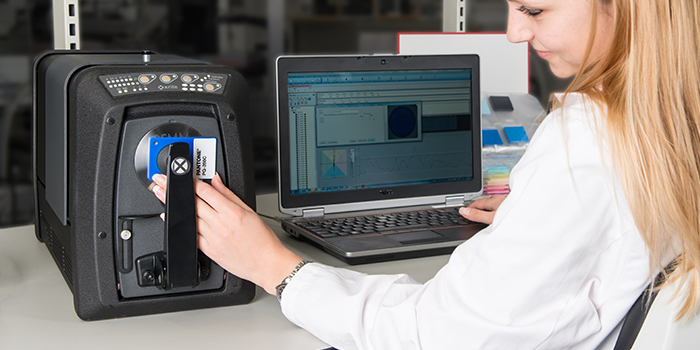

Technically, we are not trying to measure metamerism but detect it. It can be detected through visual means, by using a light booth or Colour Assessment Cabinet (CAC) and through digital means, using a spectrophotometer or the DigiEye system, which can accurately measure colour and appearance digitally, helping predict metamerism when used in conjunction with recipe formulation software.

For dyers, paint mixers, plastics manufacturers, automotive suppliers and garment manufacturers, the first step in detecting metamerism typically begins with a colour measurement device coupled with recipe formulation software. This allows recipes to be created that are unlikely to be visibly metameric. A light booth is then used to visually check samples against the standard and detect any metamerism problems before submission or approval.

Following the appropriate steps is crucial to avoid metameric matches which lead to the elimination of wastage and delays in the production.

-

Colour Measurement

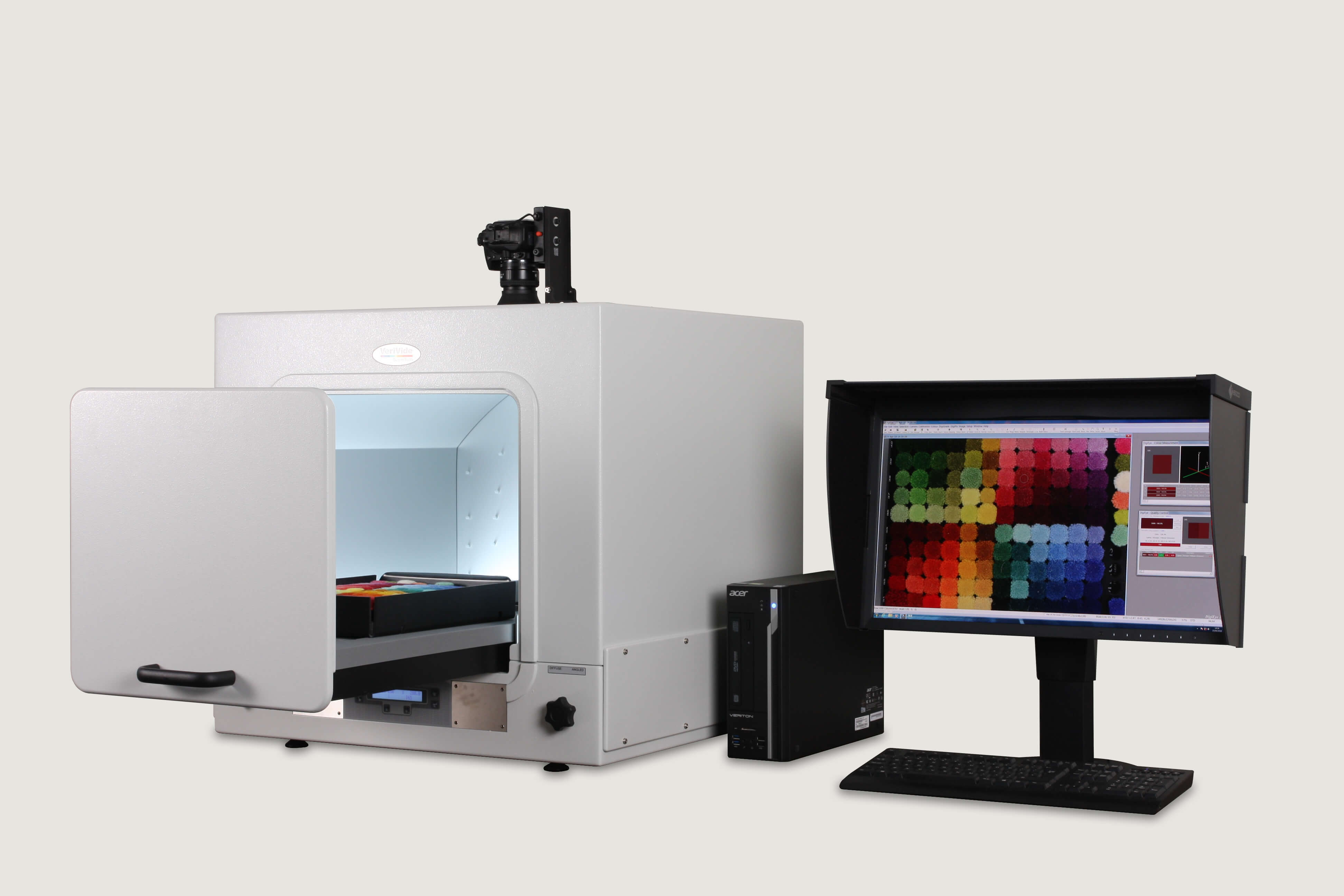

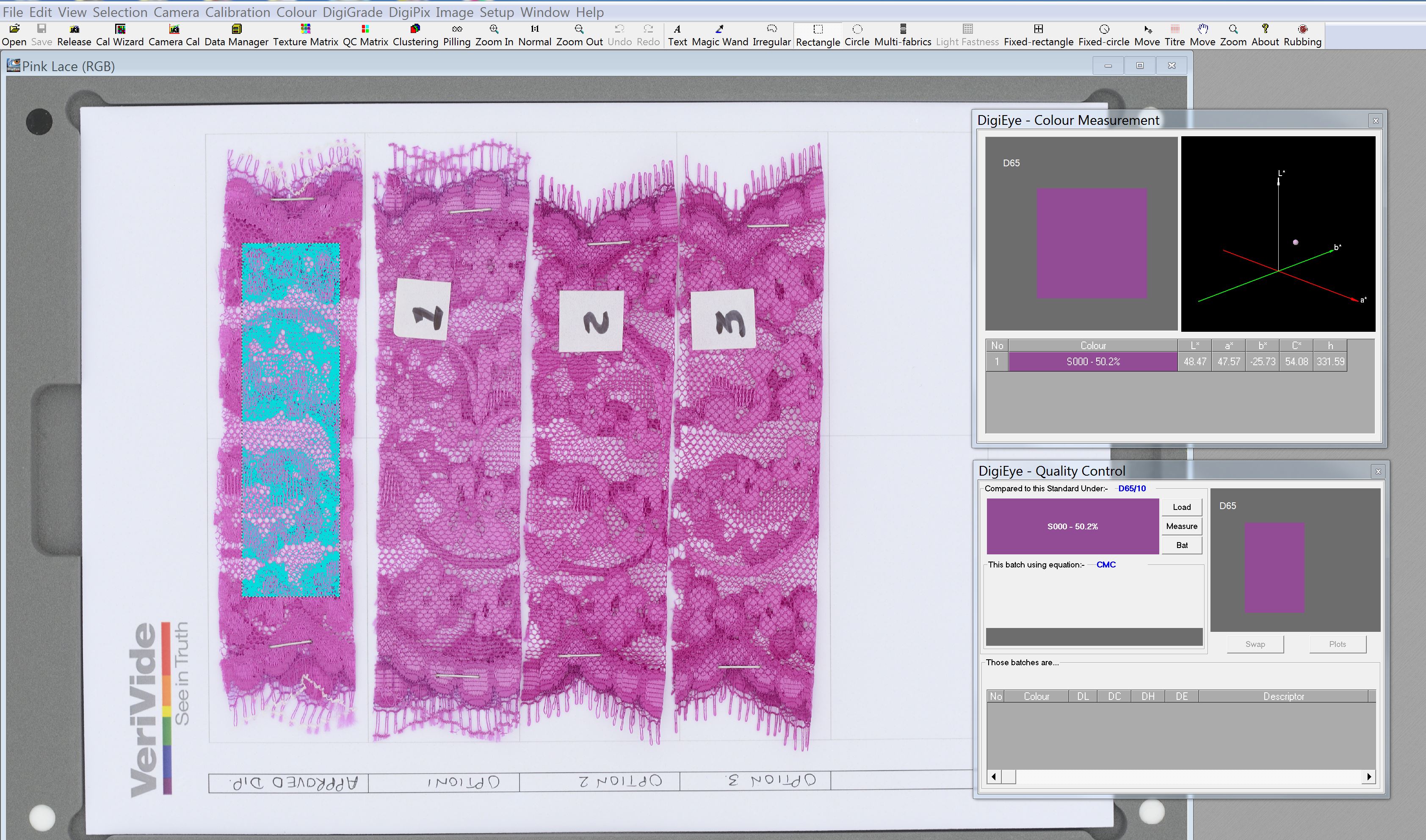

Specifying at the beginning of the design and prototyping stage the colour recipe is an important step before start assessing samples, thus colour measurement devices such as spectrophotometers or DigiEye system are needed. DigiEye is a non-contact colour and appearance measurement device which provides consistent and reliable colour data. DigiEye captures and measures the product’s colour with its appearance under provide CIE D65 standard lighting and offers different illumination geometries, including angled and diffuse lighting.

Image: VeriVide’s DigiEye System for non-contact colour and appearance measurement

Image: Spectrophotometers for colour measurement

Digital devices such as VeriVide’s DigiEye system or spectrophotometers calculate the degree of metamerism by detecting any difference in the spectral reflectance properties of the pair of colour samples. Using the standard numerical representation of the light sources used in the CAC cabinet, a colour software application makes use of the spectral data to calculate the colour difference between samples under the different light sources. This called metameric index. If the samples match for one source but do not match for any of the others, then that indicates there is some degree of metamerism between the samples. High value of the metameric index shows that the samples are metameric.

-

Visual Colour Assessment

A light cabinet is the most popular equipment used to visually check samples against the standard and detect any metamerism problems before submission or approval. VeriVide Colour Assessment Cabinets have helped scrupulous colour professionals ensure the colour and finish consistency for more than 50 years.

Using a CAC cabinet enables you to check both the quality of the colour match and for any metamerism by providing a range of different standardised light sources within a controlled viewing environment. Each light source has differing spectral properties that will clearly highlight to the observer any metamerism that may be present.

VeriVide CACs allow operators to assess samples in optimal viewing environments, providing standardised viewing conditions to international and retailer standards. Both light boxes and colour measurement devices can be used individually to measure metamerism but work best when used together.

Learn more about Best practice of Visual Assessment and achieve successful colour matching under Light Cabinets.

Image: VeriVide’s Colour Assessment Cabinets

Another way to identify metamerism is by assessing the samples digitally. DigiView allows accurate and fast Remote Colour Assessment of virtually submitted samples. Manufacturers upload the colour calibrated images of the samples in viewing stations at the retailer’s office and the Quality/ Buyer team assess the batch on-screen comparing it with a standard.

By standardising your operation procedure across your supply chain is an effective way to better control colour and identify metamerism through batches. If you want to delve deeper into the mysterious world of metamerism, or would like to talk to us about our colour assessment cabinet, then please contact us via email at enquiries@verivide.com or phone +44 (0)116 284 7790.