The ISO grey scale is a widely recognised and used method within industry, where the colour change of products can be compared and the variations are placed on a scale that ranges between 1- 5 – where 1 is bad and 5 is good.

How does the process work?

The process is fairly straightforward. First, a picture is taken of the product, for example, a packet of biscuits. Using DigiGrade Software, the colour difference is converted to a simple grey-scale grading, so that individual biscuits can be compared to the scale. If there is a big difference in colour between the biscuits, results will be placed nearer the start of the scale, however, if there is little to no variation, results will be placed nearer the end of the scale.

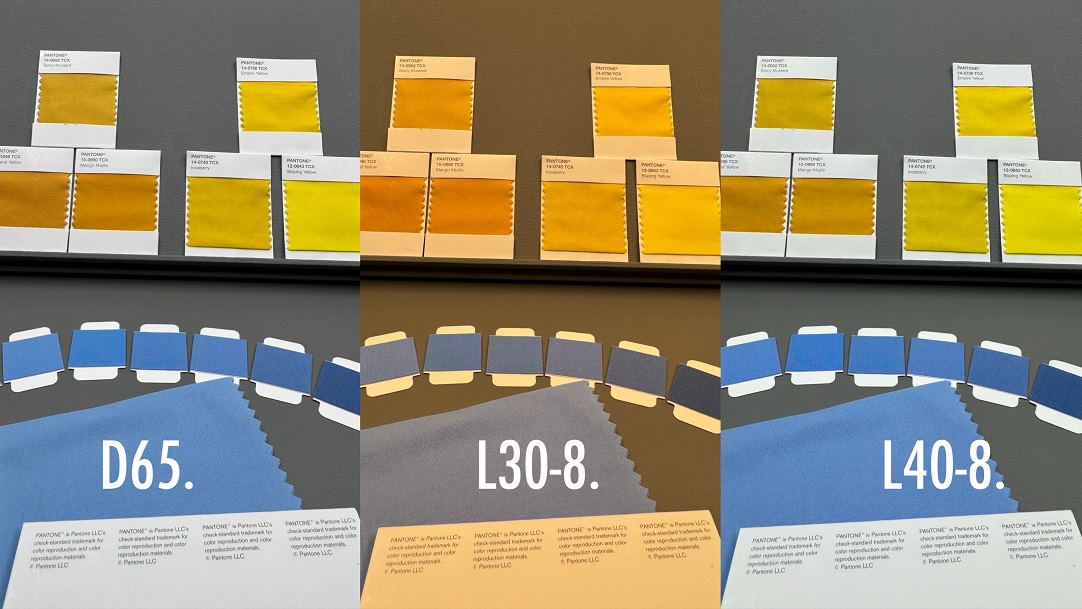

To ensure that this process is done correctly, the biscuits need to be imaged in a controlled environment because external factors (such as the light source) can impact the end results. This is why when we go through with this process, we will take the initial photo with our DigiEye system.

What is deemed acceptable on the scale?

If results are nearer the beginning of the scale, between 1 – 3, this would be deemed as unacceptable. However, if the products are placed nearer to the end of the scale, between 3 – 5, this would be deemed as acceptable.