How do Fast Food Outlets ensure colour consistency of chips and why is this important?

There are many reasons as to why fast food restaurants are so popular and successful. Some would say that it’s the convenience of not having to cook & wait for food to be ready whilst others say it is the smell, taste and overall experience of tucking into a mouth-watering burger!

Academics at the University of Cambridge have found that the number of takeaway restaurants has risen by an astonishing 45% in the last 18 or so years. In the UK there used to be 2.6 outlets per 10,000 people, however, this has risen to 3.8!

If we take a look at the bigger picture, according to Google Maps there are more than 500,000 fast food outlets across the globe!

Fun fact: Did you know that even the Queen of England owns a fast food outlet near to Buckingham Palace?

Brand consistency is essential to all chains and this is why no matter where you are in the world, a chip from any major fast food outlet will always be the same colour.

How is this achieved?

Perfect colour consistency is achieved by the following:

- Consistency in the ingredients used

- Consistency in how the chips are cooked

- Consistency in how the chips are stored

Why is colour consistency so important?

Ensuring colour consistency in their chips is very important to brand and reputation. By having one uniform colour, customers can always be certain that no matter where they are in the world, they are tucking into their favourite fast food outlet’s chip and not an alternative. Customers may be put off if the chips they are used to, look and taste different when in a different country, which would be bad news for business!

How to achieve colour consistency

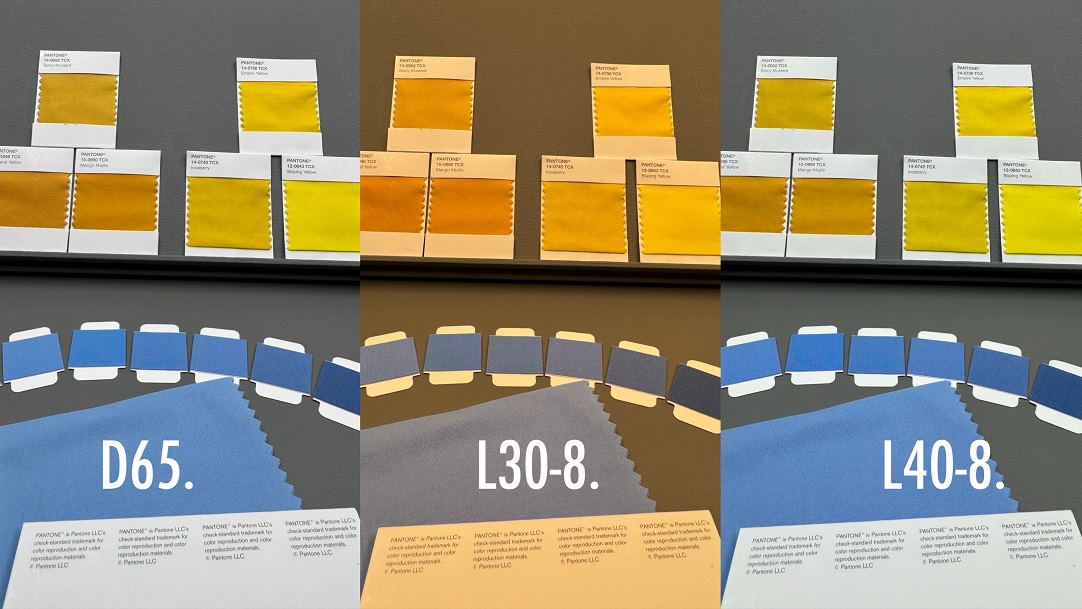

If you are in the food manufacturing industry, then colour consistency should be at the top of your priority list. Our DigiEye system can help you to achieve just this, DigiEye accurately measures the colour of specific food products. Consequently helping you to identify what ingredients need to be used and the optimum cooking and string conditions that need to be followed. Use also to make photographic colour standards for end of line QC. For more information please read the solutions for the Food and Drink industry.

To talk to one of the DigiEye team please call (0)116 284 7790 or contact enquiries@verivide.com as we would be happy to answer any question you have!