Frying Today!

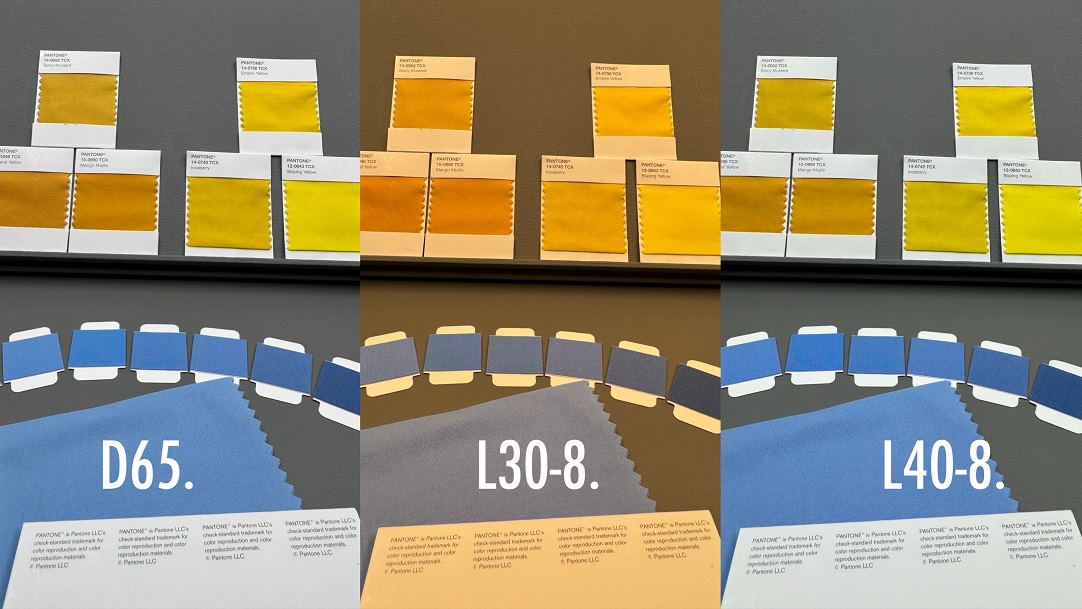

DigiEye frying colour scales were created for a brand to check quality of the potatoes.

The things we do to develop colour solutions for our clients!

We have been busy developing custom Fry Scales for a large brand owner that supplies frozen potato products to supermarkets and major food chain restaurants.

After carefully cooking (frying), we used the DigiEye System to capture a colour calibrated image which allows precise colour measurement to take place against an agreed colour standard image. Images can be stored and recalled in case of product complaints allowing further analysis if necessary.

See the steps we took in the process to create the DigiEye frying colour scales below.

Carefully weighing out the samples

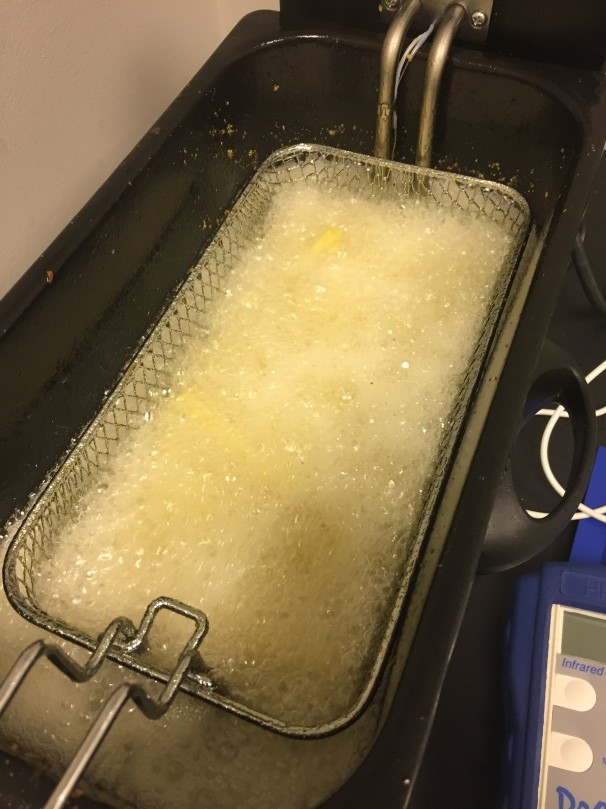

Checking the oil temperature

Timed Frying Process

Russell – Our DigiEye Application Specialist

Cooling the fries

Imaging in DigiEye

Measuring the colour of the fried product

What Chip Colour do you Prefer?

Did you know that different varieties of potato contain different amounts of sugars? And that growing conditions influence the final colour of the product?

It is well known that customers prefer the colour of food they eat to look the same each time. Food manufacturers and retailers ensure continuity in food appearance by using colour standards and scales for final appearance as well as testing the change in colour of raw ingredients when cooked.

Frying and baking colour scales are important for crisps, biscuits, pastries and bread products as well as for fries or chips.