The importance of Colour Harmony in the retail supply chain – LED v Fluorescent

The retail industry is in the middle of colour matching crisis. This may sound alarming but let us explain the current scenario.

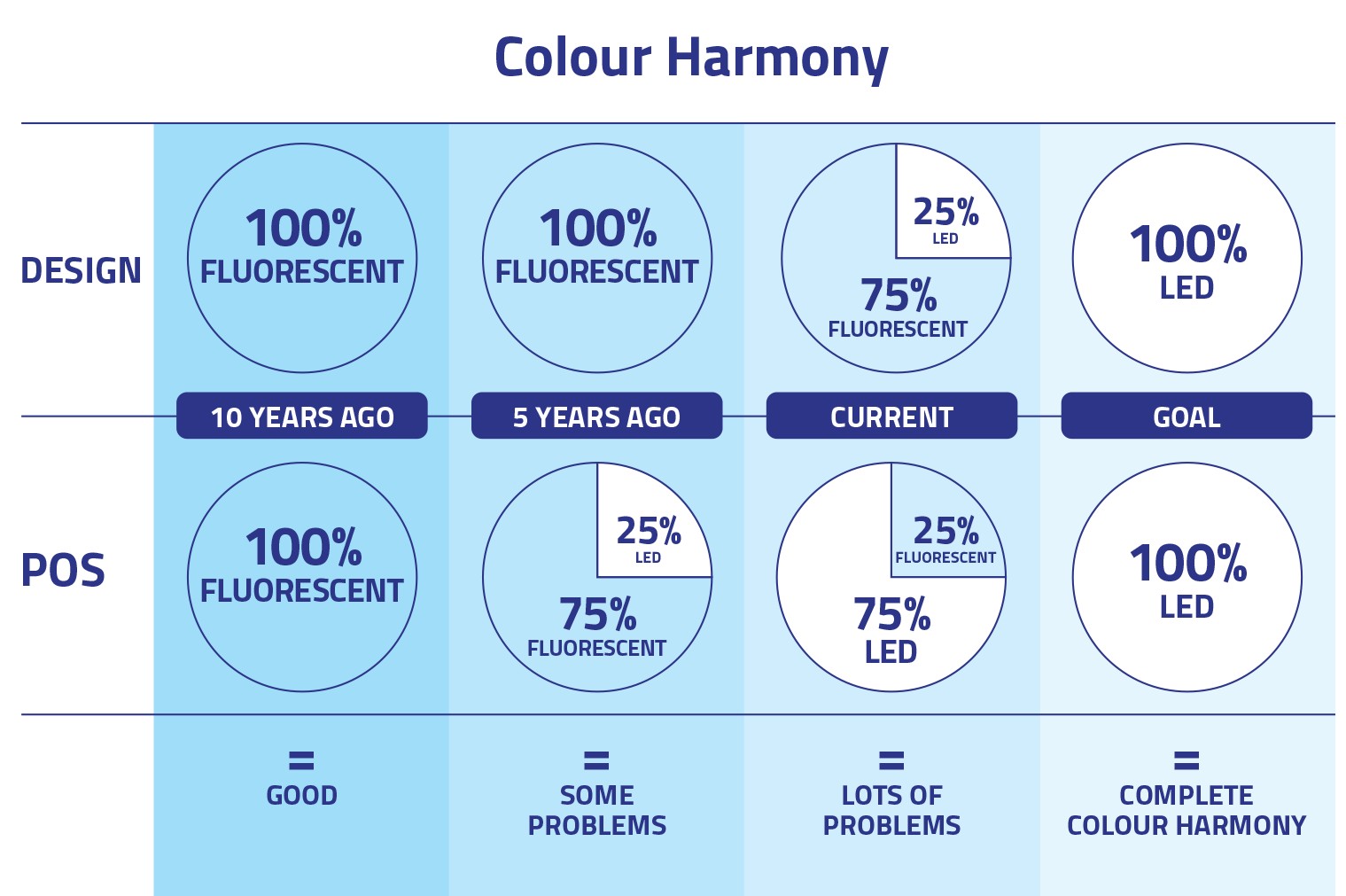

This stems from retailers adopting LED lighting in stores. It is not at all recent news; this has been slowly happening over the past 10 years. What we currently have is a colour management mismatch, where coloured product is developed and assessed under one type of lighting, and the point-of-sale lighting is another type.

LED v Fluorescent

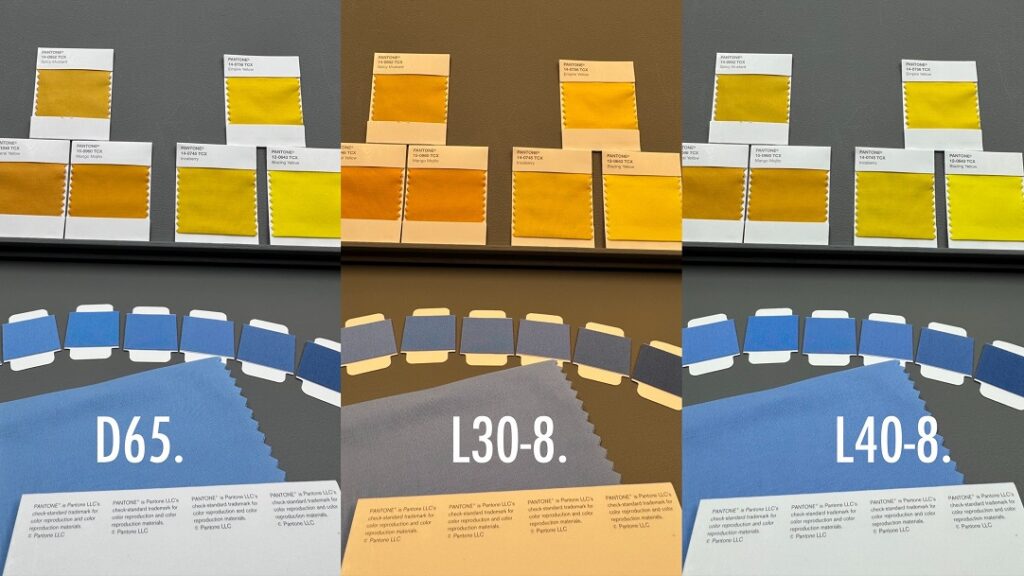

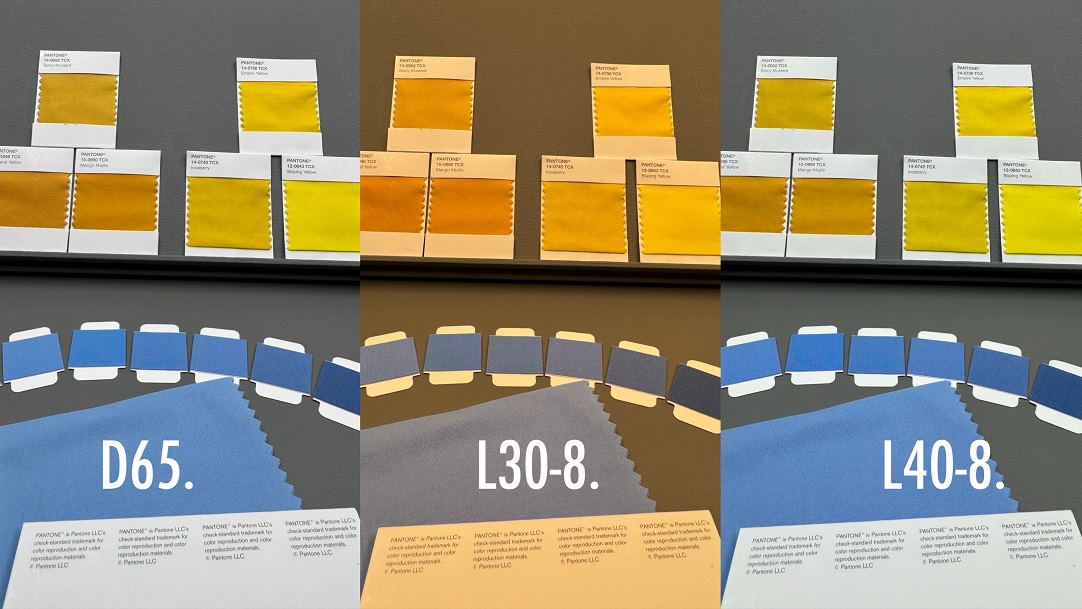

The types of lighting we are talking about in this article are the old, traditional fluorescent tubes and the new LED type. ‘We’re matching under the same colour temperature” is often stated, so is there a problem here? Yes, there is, as the same colour temperature does not mean the same light output, the spectral make-up of the light could be completely different.

“We’re matching under TL84 as specified by our customers” – this is a common statement we hear too frequently.

- Maybe the customer does not understand the differences,

- Hasn’t had time to update their colour matching specification manual,

- Or are unaware of the changeover to LED in stores and the consequences of this change.

Why has this colour matching issue occurred?

While some forward-thinking retailers and brands are aware, the adoption of LED within colour matching light booths remains slow. Consequently, within a supply chain, there is a mixture of some colour matching being done under fluorescent lamps and some matching being done under the new LED. This is exacerbated by the design teams working up to 18 months ahead of product arriving in store.

Accepting this, it means that some colour process issues remain unpredictable for some time to come. It is important that if merchandise is retailed in stores under LED illumination that the actual colour matching and quality control is performed under the same LED light source too.

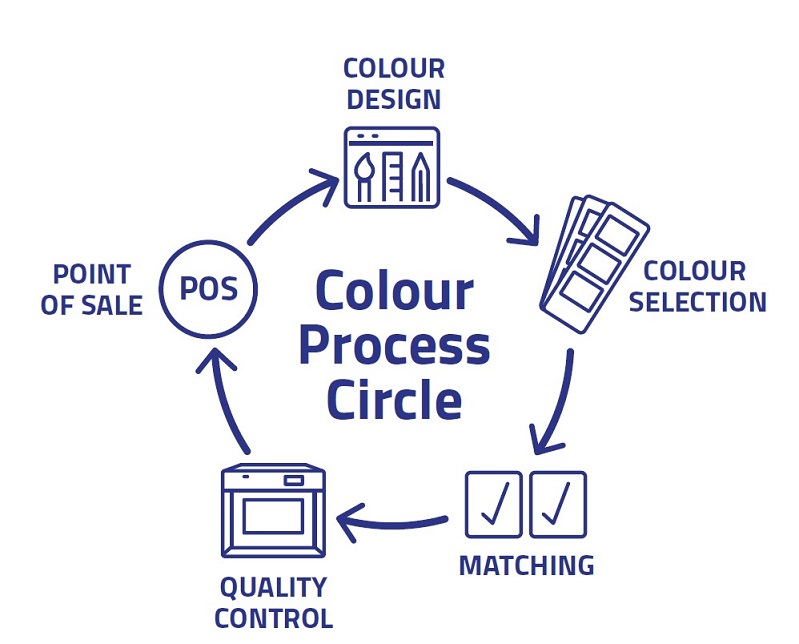

The Colour management process circle

Every stage in the process needs to address the requirement for colour harmony in store. If we examine the above colour process circle from design to point of sale, LED v Fluorescent affects the outcome.

Design and Colour Selection

It is essential that colour design and colour selection is done under the LED store light and not at the desk, against a window, or even in a light box under the traditional fluorescent lighting.

By-Passing this stage will result in some colours not looking as expected at point of sale. Designers and merchandisers spend a lot of time and effort, deciding on and selecting colours, thus ensuring complimentary or contrasting and tonal ranges are produced. If this happens under a different light source, then complete colour harmony in stores cannot be guaranteed.

Colour Application and Matching

Technically all colour formulation and colour matching needs to be under the correct primary and secondary illuminants to avoid poor matching and to eliminate any chances of metamerism. While manufacturer’s investment to use LED’s remains critical here, it is often overlooked.

The VeriVide UltraView LED booth is the ideal choice, since the UltraView includes a fully tuneable array of different light sources that satisfy many brands and retailer specifications. Production units, mills and dyehouses now need only to buy one type of light booth, instead of multiple light booths.

Quality Control

Most new LED light booths are being purchased by brands/retailers, their sourcing offices and some garment manufacturers for the final colour approval. If supplier submissions have been matched under fluorescent lighting, there is a chance of rejection at this late stage. Brands and retailers also need to ensure that designers and merchandisers have access to an LED Light Booth. Colour selections and assessment of lab dips and product developments should be under LED to ensure successful colour collections in store. Without an LED Light booth, users are working blind.

Point of Sale – The role of the Brand or Retailer

Brands and retailers need to determine which type of LED is fitted in their stores. Is it consistent across all the store estate? What happens if your brand is displayed in third party stores? Once you have the answers to these questions talk to VeriVide and, if possible, supply an example of the LED light for analysis.

When you are certain lighting in stores is consistent, and your lighting is replicated in UltraView, it is important to reissue the brand colour management specification to inform your supply chain. Missing this important step will delay conformity in your supply chain and lead to colour issues remaining for years to come.

Bring it Back – The need to restore “Colour Harmony”

Ten years ago, colour was probably being controlled quite well, but as soon as some stores introduced LED Lighting (mainly as an eco or cost measure ), the quality of colour appearance and harmony was sacrificed. About five years ago problems associated with colour harmony began to show.

Currently we can only predict further problems until all colour design, colour selection and technical colour matching is being done purely under LED lighting. This is a goal that we should all work towards to ensure colour consistency in the retail supply chain.