Any colour can appear different under different light conditions, it is a naturally occurring problem and happens every day. The difference may be extreme and obvious. For example, a car that is bright red in daylight may appear brown under sodium street lighting. But in supply chains, even minor differences in perceived colour can be problematic.

Retailers and brands introduce greater colour consistency by specifying a range of lighting options under which their products must match the colour standard. VeriVide light booths such as UltraView support colour consistency.

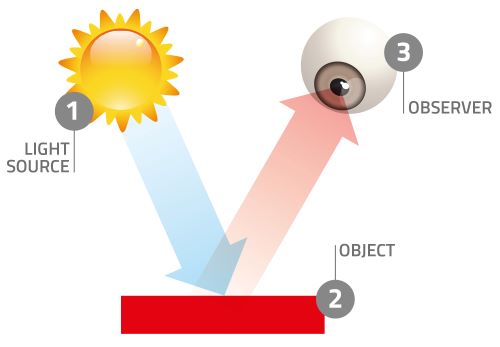

There are three elements involved with colour; the light source, the object and an observer.

Firstly, we need light, as we do not see colour in the dark! This can be from the sun, a flame or an artificial source. Secondly, is the object, which doesn’t show colour until the light falls on it. This can be anything, a pen, jumper, your neighbour’s cat, for example. Finally, the observer, to view the colour and interpret it. This can be a measurement instrument or a camera, but we cannot forget about the original observer – you! The human eye and brain combination, the eye purely being the apparatus of vision whereas the brain actually interprets what we see. When we look at something, colour is interpreted in terms of its attributes; green-red, blue or yellow, white and black.

If any of these elements change, so does the colour. Colour is very unpredictable depending on the source of light, what you’re looking at and who is looking at it! This is where VeriVide’s range of colour assessment and standards solutions provide the ideal environment for viewing colour by enabling standardization for each of the three elements, ensuring repeatability each time. Consistency is key!

Colour accuracy is a major concern for manufacturers asked to supply products in very precise shades. Colour checking in natural daylight won’t work because there is no such thing as uniform daylight. It differs according to time of day, season, location, climate, weather and atmospheric conditions. As a result, colours that look right when manufactured may look wrong when delivered. And if disputes then arise, how are they to be resolved?

The VeriVide solutions are based on two key elements:

– Standardised artificial light sources

– Digital colour assessment

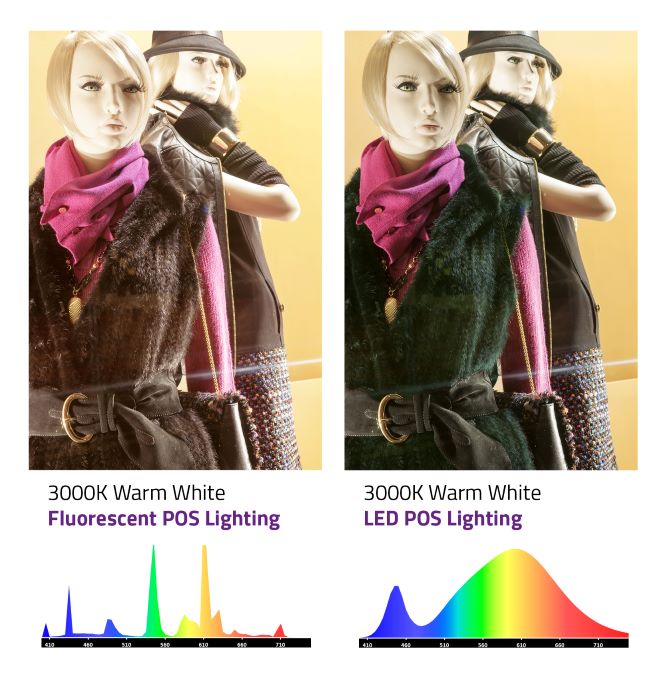

If everyone in a supply chain uses the same agreed VeriVide light source, variations in natural light become irrelevant. Colour can be viewed and measured in exactly the same lighting conditions at every stage of design and product development. VeriVide lamps mimic daylight to international standard D65 or to other standards specified by major retailers. Colour Assessment Cabinet LED P.O.S. ensures colour consistency under LED in-store lighting to eliminate colour communication problems for brands and retailers.

VeriVide’s DigiEye is the first camera-based system to make the transformative leap from human (subjective) to automated (objective) colour measurement. DigiEye assesses colour rapidly, accurately, impartially, economically – and globally when supply chain partners all use DigiEye to share data. The potential of DigiEye is recognised increasingly in sectors with no strong tradition of colour assessment. For example, in food and pharmaceuticals, where DigiEye can convert colour and appearance data into reliable information about product quality.

Colour assessment plays a growing role in quality assurance. In order to get reliable and consistent results, there are three essential requirements;

Light Sources

VeriVide lamps take care of all the science, but for the record, finding the right light source for a given application depends on three factors:

Standardised Viewing Conditions

Best practice is to use VeriVide Colour Assessment Cabinets. These ensure an identical viewing environment throughout the supply chain. Colour assessment cabinets must have neutral and blemish-free matt grey interiors and a high quality, distortion-free lamp reflector. It is good practice to offer colour perception testing to personnel involved in making colour decisions.

Capturing Objective Data

VeriVide’s DigiEye system is the innovation that transforms everything. DigiEye is a camera-based system that digitises and stores data in a form that is totally objective and authoritative.

DigiEye’s other advantages – speed, versatility, economy – give it unlimited potential for much wider industrial applications. Colour data can now be used cost effectively to measure non-colour characteristics such as product freshness and ingredient distribution. Digitised data can also, of course, be communicated globally and shared by other DigiEye systems in the same supply chain or enterprise network.