Visual Assessment to ISO 3664:2009

Assessment to ISO 3664:2009 standard for colour and appearance is possible using VeriVide D50 lamps and CCC cabinets. Now superseded by UltraView which has LED D50 illumination, the two levels of illumination intensity are achieved when dimming of D50 is pre-programmed.

Visual assessment is indispensable to quality control procedures in the printing and graphics industry. Even when accurate colour and density measurements are used, in the end the human eye makes the final decision.

The human observer, typically the photographer, designer, print press operators or publisher will examine colour and visual quality of prints, proofs and photographic transparencies before submitting to the client.

As the surface print being viewed only has the ability to absorb or reflect light, it is ultimately the light source and viewing conditions that determine the final appearance. Which gives rise to the question, under which viewing conditions should professionals evaluate appearance?

D50 illumination

Controlling the lighting and viewing conditions is critical to avoid inaccuracies and misunderstandings in colour reproduction or when communicating colour with your clients. Colour problems may cost you a lot of money and delays in the reproduction that could risk the relationship with your customer.

The International Standards Organisation (ISO) and their representative committees settled on CIE illuminant D50 as the reference light source for the printing and graphics industry. CIE D50 is a simulation of warm natural daylight with a correlated colour temperature (CCT) of 5000 Kelvin. This is ultimately defined by the published CIE D50 spectral power distribution.

“The illumination used to view colour photographic prints, photomechanical reproductions and transparencies needs to provide adequate amounts of radiant power from all parts of the ultraviolet and visible spectrum to avoid distorting their appearance from that observed under commonly used sources of illumination such as daylight.” (ISO 3664:2009)*

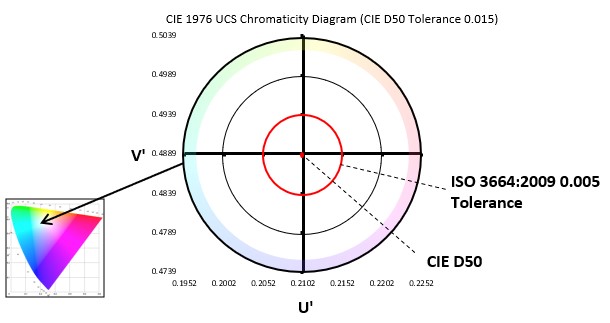

Creating accurate standardised viewing environments requires precise specifications. Colour temperature alone is not enough to accurately qualify a simulation of CIE D50.

ISO 3664:2009

ISO 3664:2009 is essentially a set of detailed specifications used by manufacturers of specialist lighting and viewing equipment to ensure accuracy and repeatability for users when visually assessing colour and appearance. By default, the specifications are also used to set tolerances when testing and certifying the performance of viewing equipment.

“If accurate colour is important to you and your clients, you need to be confident that your printed work is always viewed in controlled and consistent lighting conditions.” (Steve Tongue, Product Development Manager at VeriVide)

Criteria

The criteria set out in ISO 3664:2009 include:

- Chromaticity: defined by co-ordinates within a designated colour space. In this case the CIE 1978 uniform colour space. ISO 2664:2009 sets a tolerance of 0.005 around the centre point for CIE D50 illuminant.

- Light Intensity: the amount of light falling on the viewing surface. Measured in Lux, the standard sets a target 2000lx +/- 500lx for prints and proofs.

- Colour Rendering Index: as specified in CIE 13.3-1995 compares the effect of a test illuminant with a reference illuminant on the appearance of a set of test colours. A score is awarded for each test colour up to a maximum of 100. A score of 100 indicates no perceived difference between the reference and test illuminant. ISO 3664:2009 states the general colour rending index (the average of the first 8 test colours R1-R8) should be greater than or equal to 90 additionally, no separate colour from 1 to 8 shall score below 80.

CRI Graph for VeriVide D50 Lamps

Image: CRI Graph for VeriVide D50 Lamps

- Metamerism index: Using the CIE 23603 method for assessing daylight simulators, ISO 3664:2009 requires an MI score for the visible range of less than 1.0 and less than 1.5 for the UV range. This is a significant change from the previous version of the standard; ISO 3664:2000 in which the MI UV target score was less than 4. Setting a tighter tolerance for the UV score helps to ensure there is sufficient UV wavelengths present to excite optical brightening agents in substrates. Consequently, giving a closer representation of how the print would appear in natural daylight.

Is your quality control taking place under the correct viewing conditions?

Assessment to ISO 3664:2009 standard for colour and appearance is key in quality control of prints. VeriVide CIE D50 daylight lamps meet all applicable criteria set out in ISO 3664:2009.

Colour Control Cabinets (CCC’s) use a unique method for eliminating viewing flare, allowing for critical comparisons of prints and reproductions.

VeriVide Colour Control Cabinet

Image: VeriVide Colour Control Cabinet

We offer onsite audits and regular certification of your viewing equipment in the UK.

Call us for more details on +44 (0) 116 284 7790 or email us at sales@verivide.com .

*ISO (2015), ISO 2664:2009 Graphic Technology and Photography – Viewing Conditions, available from https://www.iso.org/standard/43234.html