Checking the product at various production stages is essential to meet expected quality standards as well as product safety. VeriVide can provide a range of equipment to ensure high quality products are produced every time.

Having guaranteed high quality products every time is a dream come true, right? Checking the quality requires rigorous testing, inspection, and evaluation against an agreed standard. Without testing the quality of the material or end product, it can result in customer returns, a loss in sales and an unwanted product or even damaged reputation.

We can help you evaluate every kind of surface from glass bottles to laminate for doors and flooring and from denim jeans to knitwear, enabling anomalies to be identified quickly to improve consistency and quality, managing flaws and imperfections before they are a problem to the consumer.

Some examples of the type of appearance issues include contamination, scratches and other surface damage or uneven application of coatings. Laminates for flooring or cupboard doors are assessed under a Luminaire. Undissolved particles and contamination in liquids can be identified by using the equipment we designed for this purpose – the CAC Particulate cabinet.

Many manufacturers of food and drink packaged in glass bottles use VeriVide’s Planning Tables to identify scratches and other flaws on the glass before the product leaves the factory. This is an integral part of the Quality Control process preventing damage during transit and poor consumer perception.

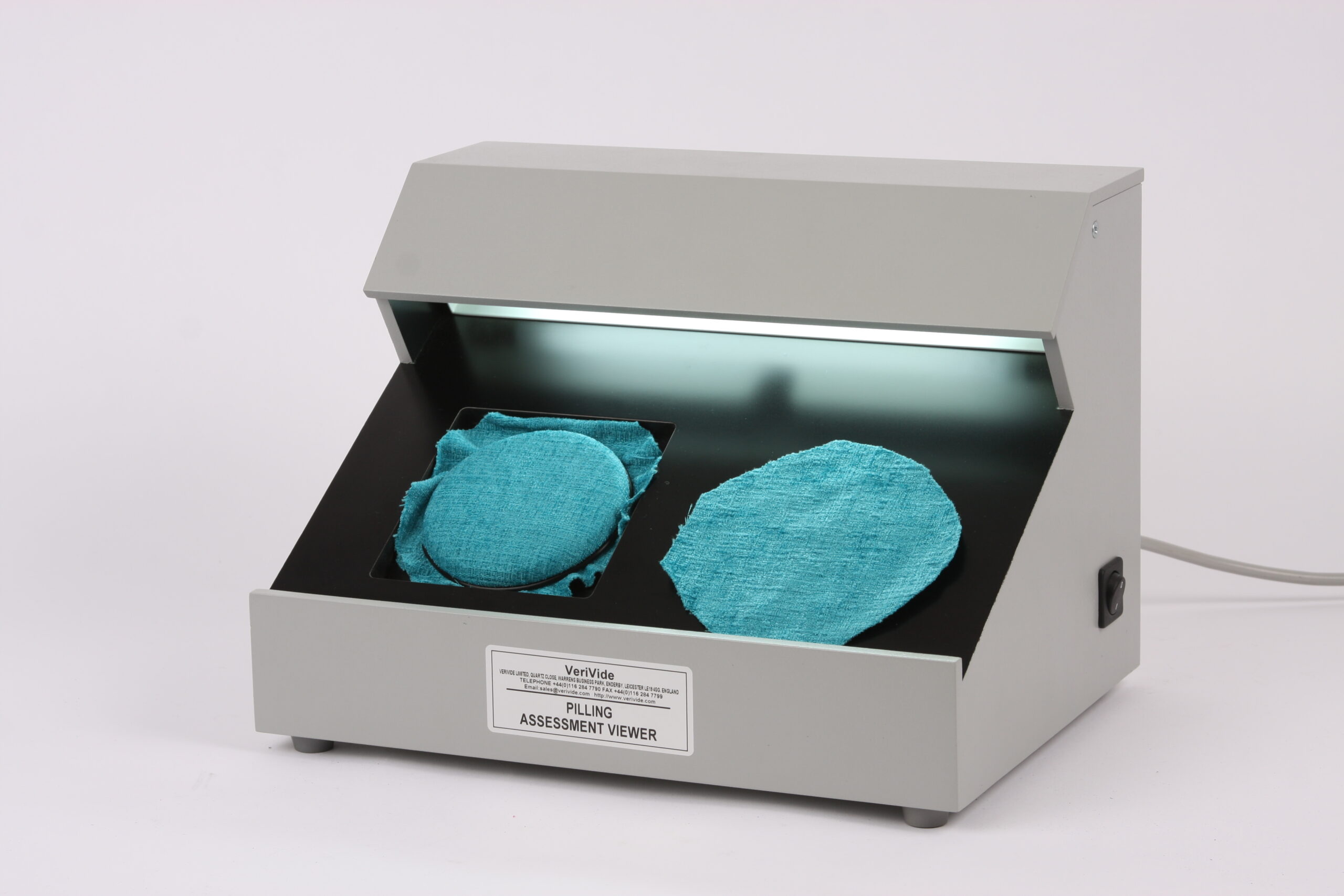

Appearance evaluation is just that – comparison of the product against the expected appearance standard, before and after the product has been subjected to tests to simulate wear and tear during use. VeriVide has developed several products for assessing the appearance of textile materials. Our products are referenced in the standard Test Methods for tests such as pilling, snagging and crease recovery. VeriVide’s Viewing Boards and Pilling Assessment Viewer are designed to meet the requirements for these tests. Once you have the before and after test samples, they can be graded, which assists with decision making about the material or finishing process to use or the care labelling of the product ensuring the product meets its specification.

The appearance of large items can be assessed under VeriVide Luminaires or inside the 1300mm DigiEye cube and don’t forget that colour fastness can be assessed visually in VeriVide’s Light Booths or digitally with DigiEye using DigiGrade software.

If you work with textiles then our range of textile testing equipment is what you need! These range from a Pilling Assessment Viewer to an Accelerotor viewer, all designed to show you the wear and tear on the fabric you are using.

If you are using other materials, such as wood, glass, even liquids, colour and appearance evaluation is still essential. Our lighting cabinets provide correct lighting environments, whilst Luminaires provide the correct lighting environment, but on a larger scale. Please speak to one of our friendly members of staff who are here to provide advice and expertise, email us at enquiries@verivide.com or call +44 (0)116 284 7790.